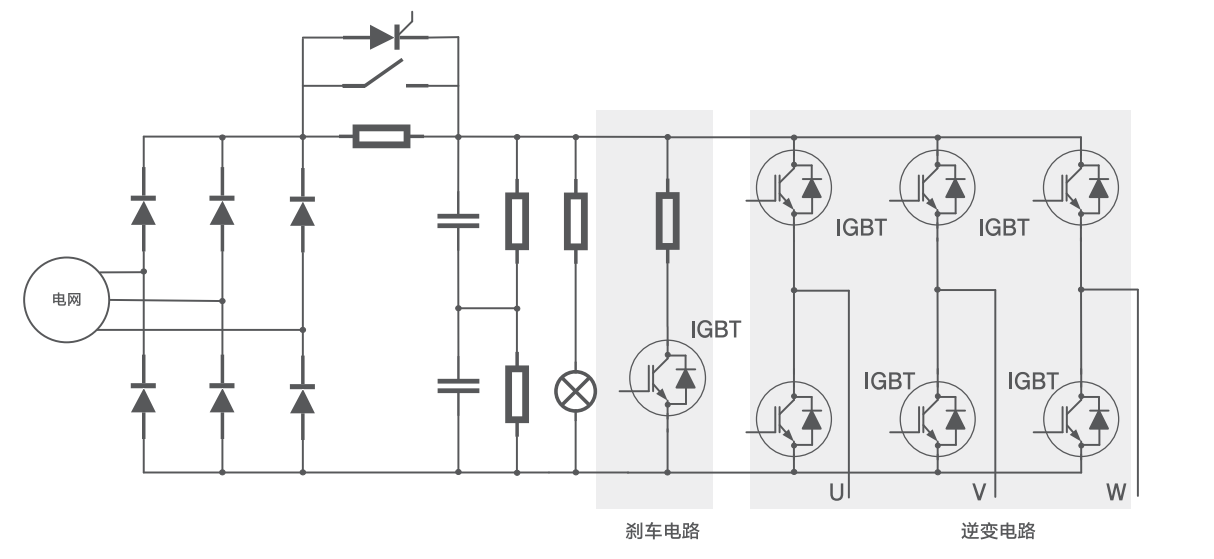

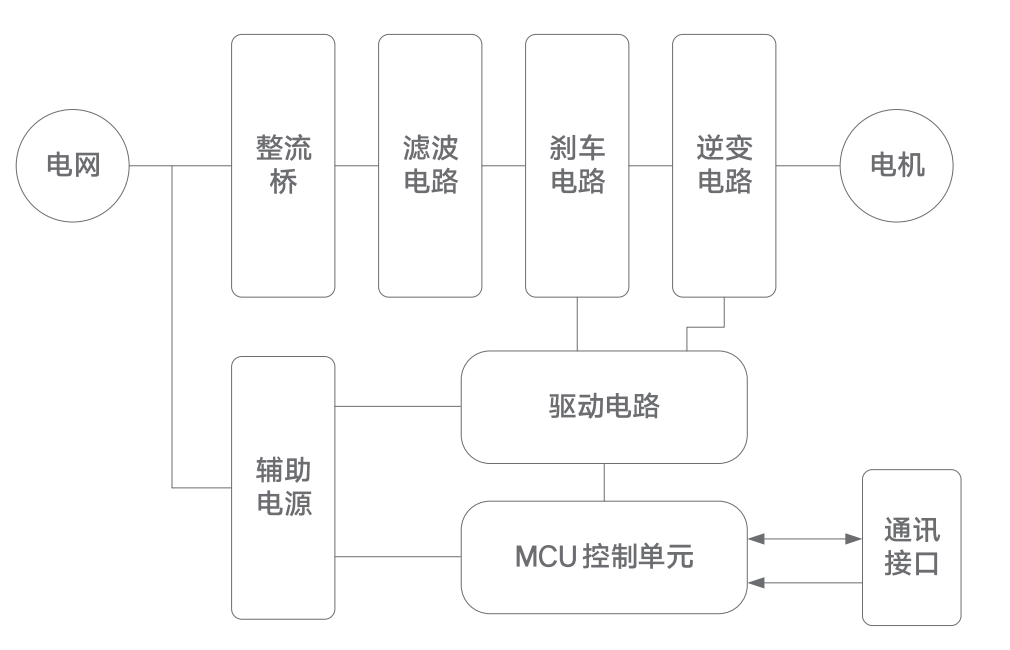

According to statistics, about 50% of the world's electricity is used for industrial variable frequency drives, mainly used in fans, pumps and air compressors. By adopting variable frequency speed regulating device, the speed and torque of the motor are controlled to realize the optimization of the motor operation process, which can significantly save energy. Frequency converter has a wide range of applications, the application environment is different, there will be frequent overload, heavy load and other operating conditions, customers need strong power impact resistance, short circuit resistance ability for a long time, the IGBT device with high reliability.

The new generation of 1200V IGBT products, based on the trench grid electric field cutoff technology (FS), optimized the chip structure for the application of motor drive system, adopted a more advanced thinning process, reduced power loss, enhanced robustness (strong short-circuit energy), and improved the reliability and production stability of IGBT devices. Greatly improve the service life of IGBT devices.

At the same time, for the auxiliary power application of motor drive system, Eco Micro has launched MOS devices with voltage resistance up to 1500V, providing customers with full-power solutions.